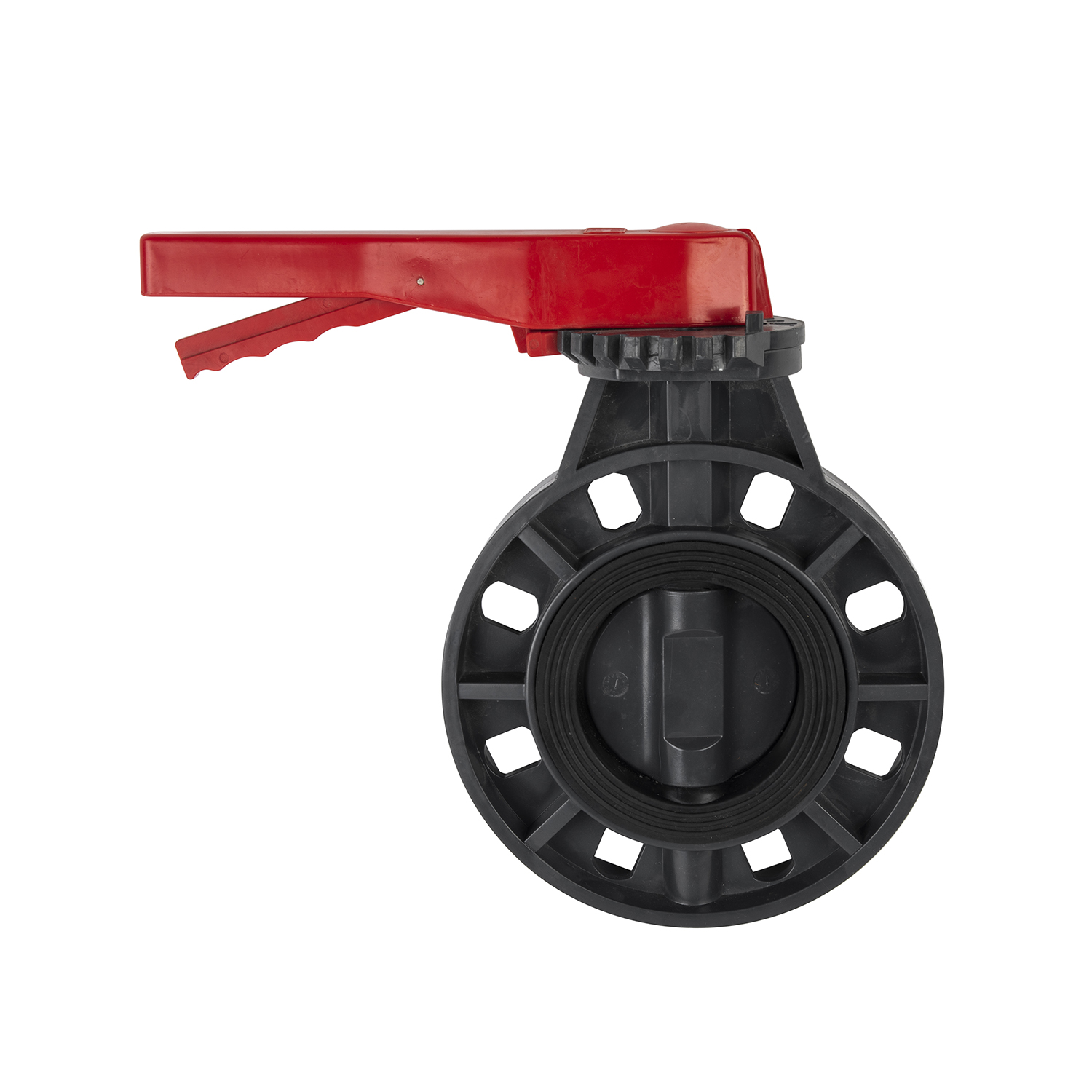

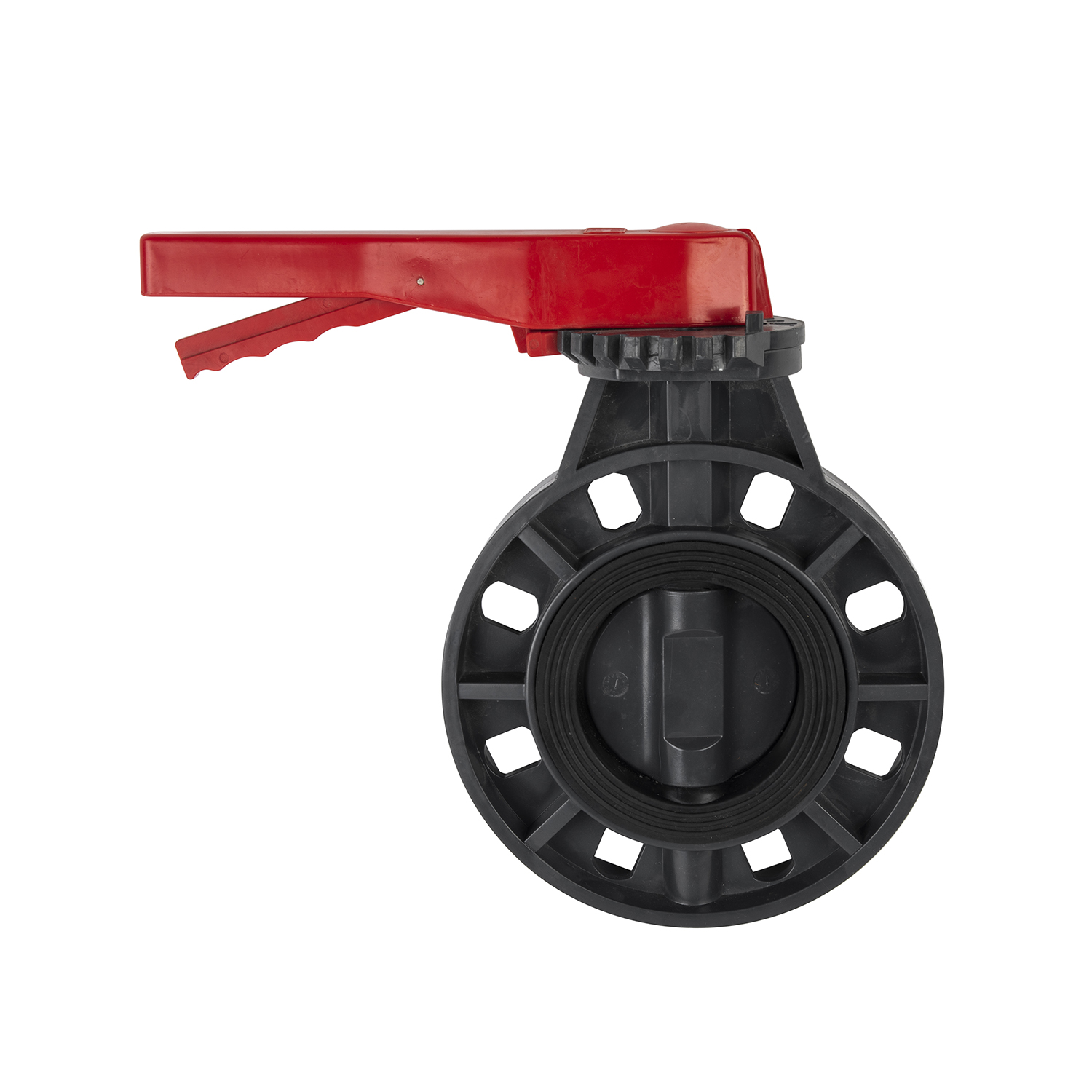

UPVC Ball Valve Specifications

Attribute | Specifications |

Size Range | 1/2" to 8" |

Standards | ASTM, DIN, JIS, BS |

Shape Options | Octagonal ball valve, Compact ball valve |

Connection Options | Threaded connection, Socket connection |

Body Material | UPVC |

Seat Seal Material | TPE |

Ball Material | PP |

Handle Material | ABS |

O-ring Seal Material | NBR |

Characteristic Description

Basic Specifications

The HJ PVC Ball Valve (PVC Ball Vave) covers a versatile size range from 1/2" to 8", catering to diverse piping requirements. It offers two distinct shape options to fit different installation scenarios: the octagonal ball valve for stable operation and the compact ball valve for space-constrained environments. For connection flexibility, users can choose between threaded connection (ideal for secure, detachable joints) and socket connection (perfect for seamless, leak-proof assembly).

Material Composition

Every component of the PVC Ball Vave is selected for optimal performance and longevity:

Body: Made of UPVC (Unplasticized Polyvinyl Chloride), ensuring corrosion resistance, high pressure tolerance, and compatibility with most fluids.

Seat Seal: TPE (Thermoplastic Elastomer) provides excellent sealing performance and wear resistance.

Ball: PP (Polypropylene) offers chemical stability and smooth operation.

Handle: ABS (Acrylonitrile Butadiene Styrene) delivers a sturdy, ergonomic grip for easy operation.

O-ring Seal: NBR (Nitrile Butadiene Rubber) enhances leak prevention with superior elasticity.

Market Research

Target Industry Demand

The global PVC ball valve market is driven by the growing need for efficient fluid control in sectors like water treatment, chemical processing, construction, and agriculture. Industries prioritize valves that are corrosion-resistant, easy to maintain, and compliant with international standards—all features that the PVC Ball Vave embodies. Residential and commercial buildings also demand reliable valves for plumbing systems, where the compact design and leak-proof performance of HJ’s PVC Ball Vave gain significant traction.

Competitive Edge in the Market

Unlike generic PVC ball valves, the PVC Ball Vave addresses key pain points of users: frequent leaks, difficult maintenance, and stiff operation. Its innovative sealed design and easy-to-remove handle fill the gap in the market for low-maintenance, high-reliability valves. With compliance to multiple international standards, it meets the requirements of global markets, from North America (ASTM) to Europe (DIN) and Asia (JIS, BS).

Key Features

Innovative Sealing Design

HJ reimagines the traditional ball valve structure by integrating the O-ring seal within the valve body rather than the handle assembly. All sealed components are molded and assembled as a single unit, eliminating the risk of loose parts and enhancing overall reliability. This design significantly reduces leakage issues common in conventional valves.

Effortless Maintenance

The PVC Ball Vave features a detachable handle that simplifies maintenance and repairs. Users can easily replace the handle if damaged, or add an extra O-ring seal between the handle and body to address potential leaks—no complex tools or professional skills required. This saves time and costs for both installers and end-users.

Smooth Operation for Large Sizes

For valves 2.5" and larger, HJ has upgraded the mold design to enable bidirectional opening. This not only expands installation flexibility but also reduces torque requirements. The handle turns smoothly, even for larger valves, making operation effortless and reducing user fatigue.

Performance Meets

International Standard Compliance

The PVC Ball Vave adheres to stringent international standards, including ASTM, DIN, JIS, and BS. This ensures compatibility with global piping systems and guarantees that the product meets the highest quality and safety benchmarks for fluid control.

Rigorous Leakage & Pressure Testing

Every unit of the PVC Ball Vave undergoes a strict quality inspection before packaging. The valve is injected with high-pressure air equivalent to 16pn water pressure, and the pressure is maintained until the next day to detect any potential leaks. This rigorous testing process ensures that only leak-proof, high-performance valves reach customers.

Why Choose Us

Engineering Excellence

HJ Plastics prioritizes innovation in product design. The PVC Ball Vave’s unique sealed structure and upgraded mold design reflect our commitment to solving real-world user problems. Our R&D team continuously optimizes products based on market feedback, ensuring we stay ahead of industry trends.

Uncompromising Quality Control

From material selection to final assembly, every step of the production process is monitored by professional quality inspectors. We use only premium materials and advanced manufacturing techniques to ensure consistent product quality and durability.

Customer-Centric Support

We provide comprehensive customer support, including technical guidance for installation and maintenance. Our team is dedicated to addressing customer inquiries promptly, ensuring a smooth user experience from purchase to long-term use.

FAQ

What fluids is the PVC Ball Vave compatible with?

The valve is suitable for most non-corrosive fluids, including water, mild chemicals, and neutral liquids. It is ideal for water treatment, plumbing, and general industrial fluid control. For aggressive chemicals, contact our technical team for compatibility confirmation.

How do I maintain the PVC Ball Vave?

Maintenance is simple: the detachable handle allows easy replacement or inspection. If leakage occurs, add an extra NBR O-ring seal between the handle and body. Regularly clean the valve surface to prevent dust accumulation, and avoid using sharp tools that may damage the UPVC body.

Can the valve be installed in both directions?

Valves 2.5" and larger support bidirectional opening, offering flexible installation. Smaller sizes (1/2" to 2") are designed for unidirectional operation—please refer to the product manual for correct installation orientation.

Is the PVC Ball Vave suitable for high-pressure applications?

Yes. The valve is tested to withstand 16pn water pressure (equivalent to high-pressure air testing) and is suitable for most medium-pressure fluid control systems. Always check the pressure rating of your specific size before use.